U2Robotics

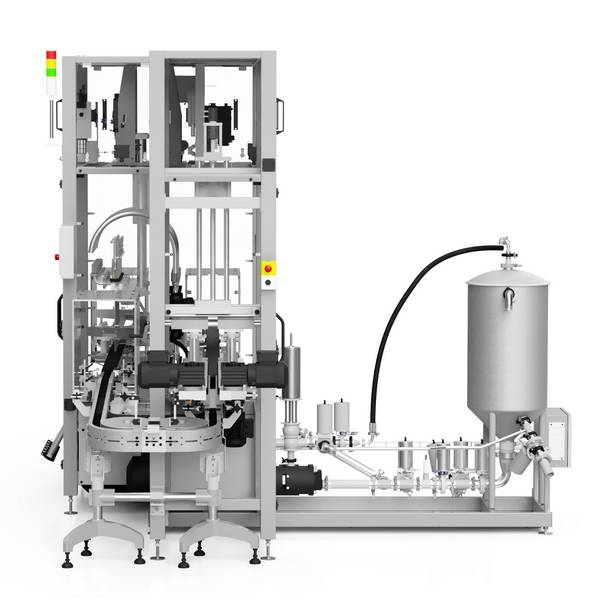

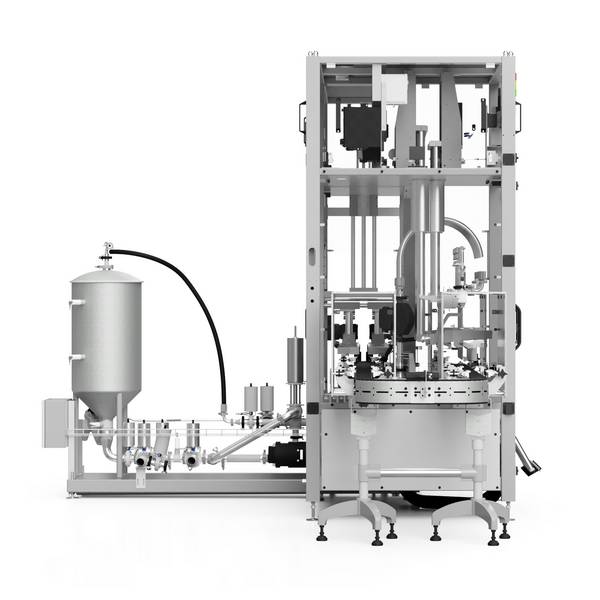

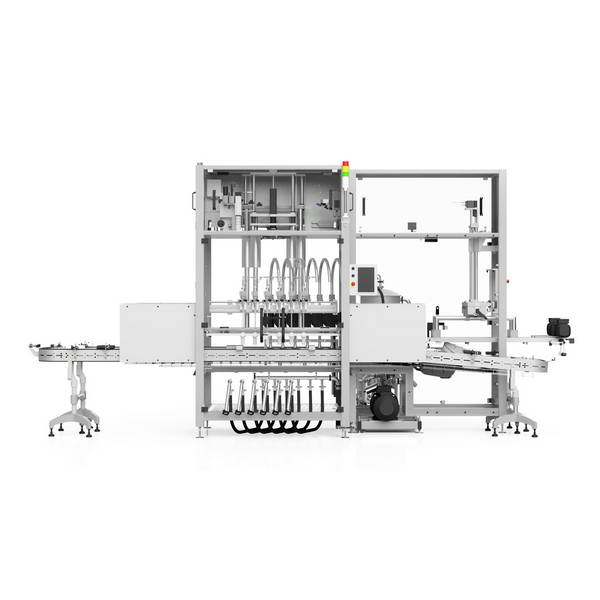

Automatic liquid machine – Cosmo Line 40 –

Cosmoline 40 has been designed for a short series of products and frequent, toolless changeovers which only take a very short amount of time.

Technical characteristics of the filling, capping and labelling line for liquids

Cosmo Line 40

The device works in the system of regulated format pucks, thanks to which any bottle shape (e.g. jars, PET bottles, cans etc.) may be served without a time-consuming and complicated changeover of the whole line.

Cosmoline filler works with a wide range of liquids (cosmetics, mineral oil, homecare, chemical, etc.). Filling by flowmeter (massflowmeter or electromagnetic) or by volumetric(pistons). Number of filling nozzles define on request depends on filling volume and machine speed (from 2 to 8).

Liquid may be taken directly from the IBC container placed next to the machine or from a special funnel located above the filler. The machine is able to work with any type of the closure. The line is also equipped with an automatic product depacker which takes out products from the pucks and feeding them for labelling. The labelling machine can perform the wraparound labelling (circular packages) or the front/back one.

– The main features and benefits of the automatic liquid line –

- All pucks are easy to changeover

- Pucks Work with any package shape and type

- The dosing line is useful for a wide range of cosmetics: soaps, shampoos and emulsions

- The filler is equipped in system to control filling volume with following the level of the nozzles to prevent splashing if required

- filling of any liquid substances from watery ones (water, acetone, alcohol) to very thick ones (honey, cream, balm)

- Filling ranges from 5 to 2000 ml

- Dosing by means of flow-meters – up to six filling stations for body lotion lines

- Dosing by means of piston-pump for skin care products

- All components which have contact with liquid dosing are easy to dismount

- Capping machines for any type of closures: cosmetic pumps, sprays/triggers, flip-tops, push-pull closures

- Possibility of automatic infeed of closures to the capper

- Closure quality control system

- Fast and easy changeover to another product

- Precise labelling of packages

- Possibility of detecting the presence of a label

- Productivity up to 45 pcs./min